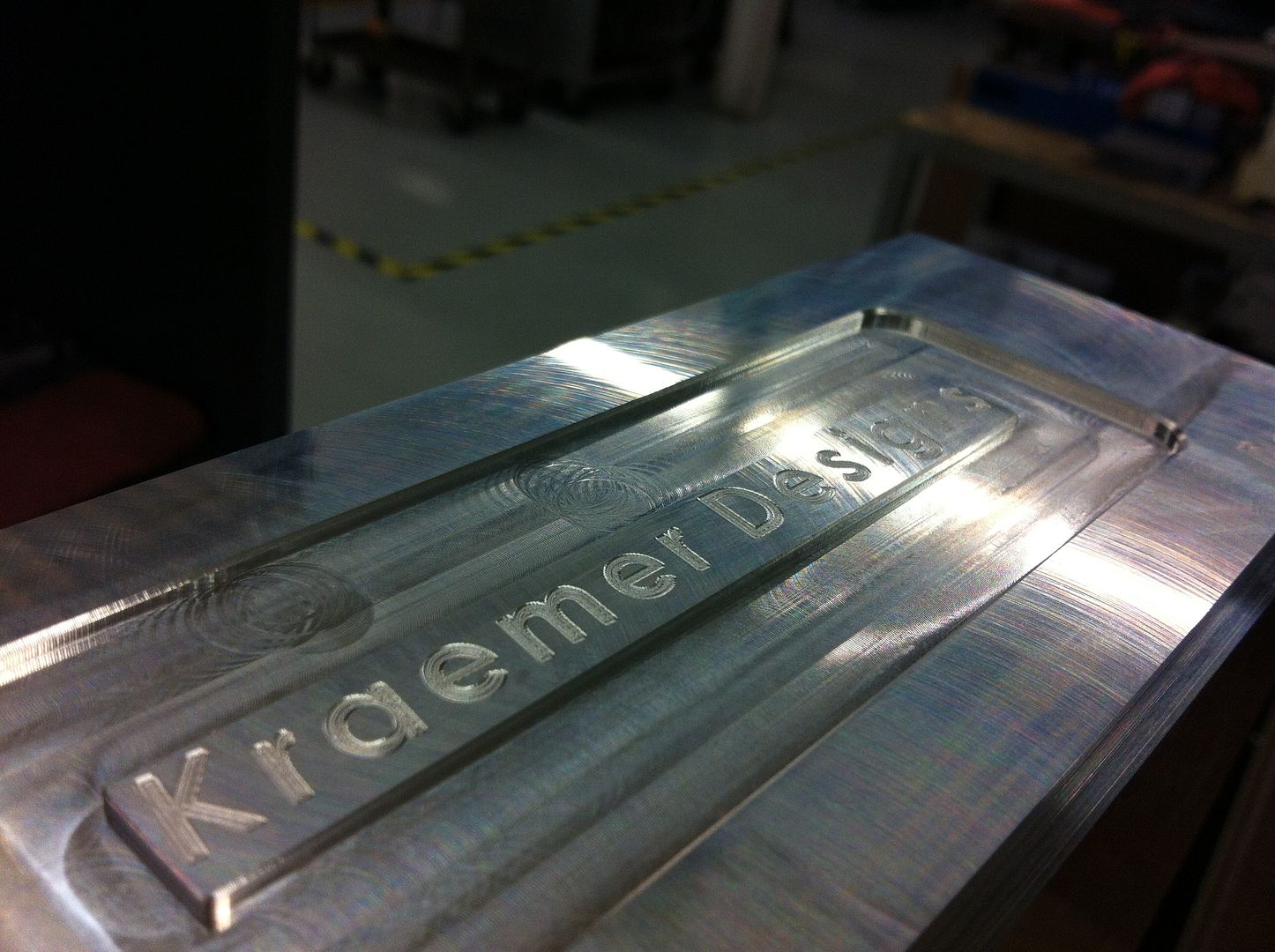

KraemerDesigns

New member

Matt... Hello & Welcome!!! You build some very nice looking gear.

Thanks Jeff! and thank you for the welcome.

Matt... Hello & Welcome!!! You build some very nice looking gear.

Thanks Joe!

I'm probably the youngest at only 25

-joe

Sadly no websites or blogs. Just thousands of pictures posted on various forums.

I should make a blog one of these days. I've got tons of old porojects and new ones to share.

Matt,

1. Great that you love the sound of your speaker's design.

* Just a remark: the front edges (sides), I think that they should be curved from their front face and going towards the sides. ...Because they abruptly bounce the high frequencies; which I don't believe to be a good idea. ...Rounded side edges would have been a better 'sound' design (mathematically measured and scientifically proven wise).

- I followed your thread right from their first conception, design, cutting, changes, and final stage. And I also read all the member's comments on them, but couldn't reply, as you well know, and that's what I thought and still think today.

2. Matt, I'll see if I can post a link on most of the stuff you produced in the last couple months or so. ...If you don't mind of course.

...Only positive criticism Matt. ...What I'd love to see is a professional audio reviewer like John Atkinson from Stereophile reviewing them.

And John is a member here.

...

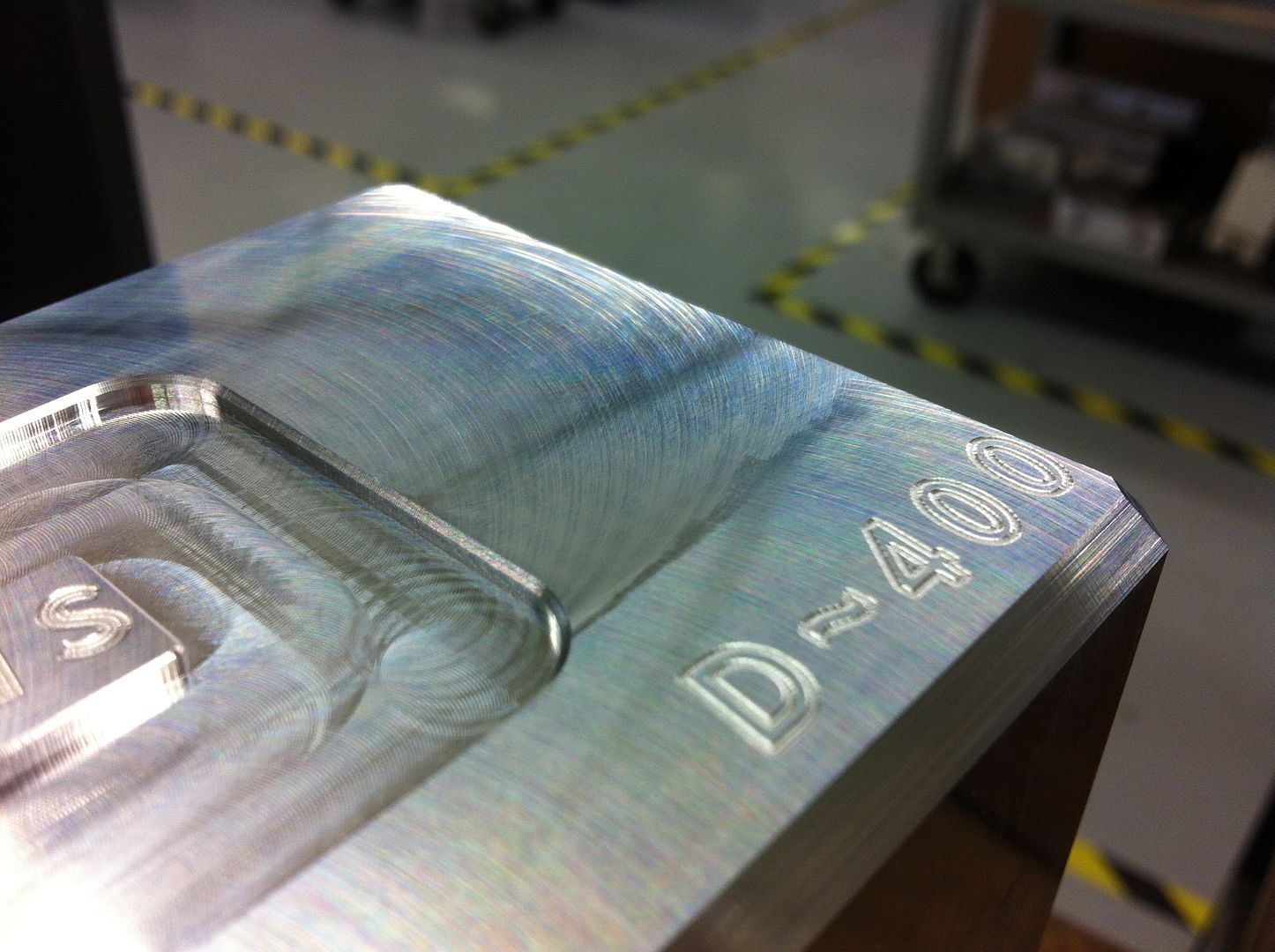

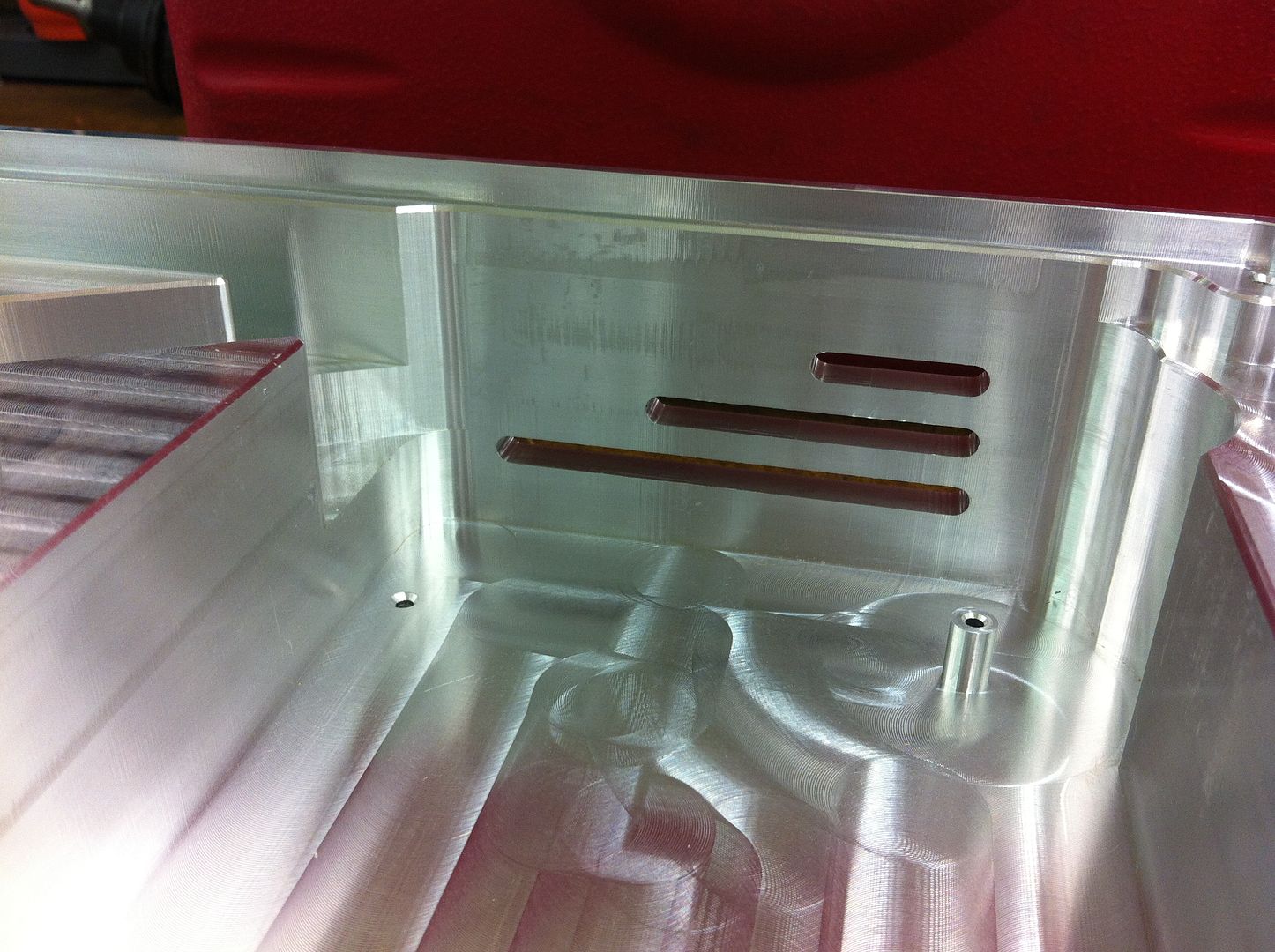

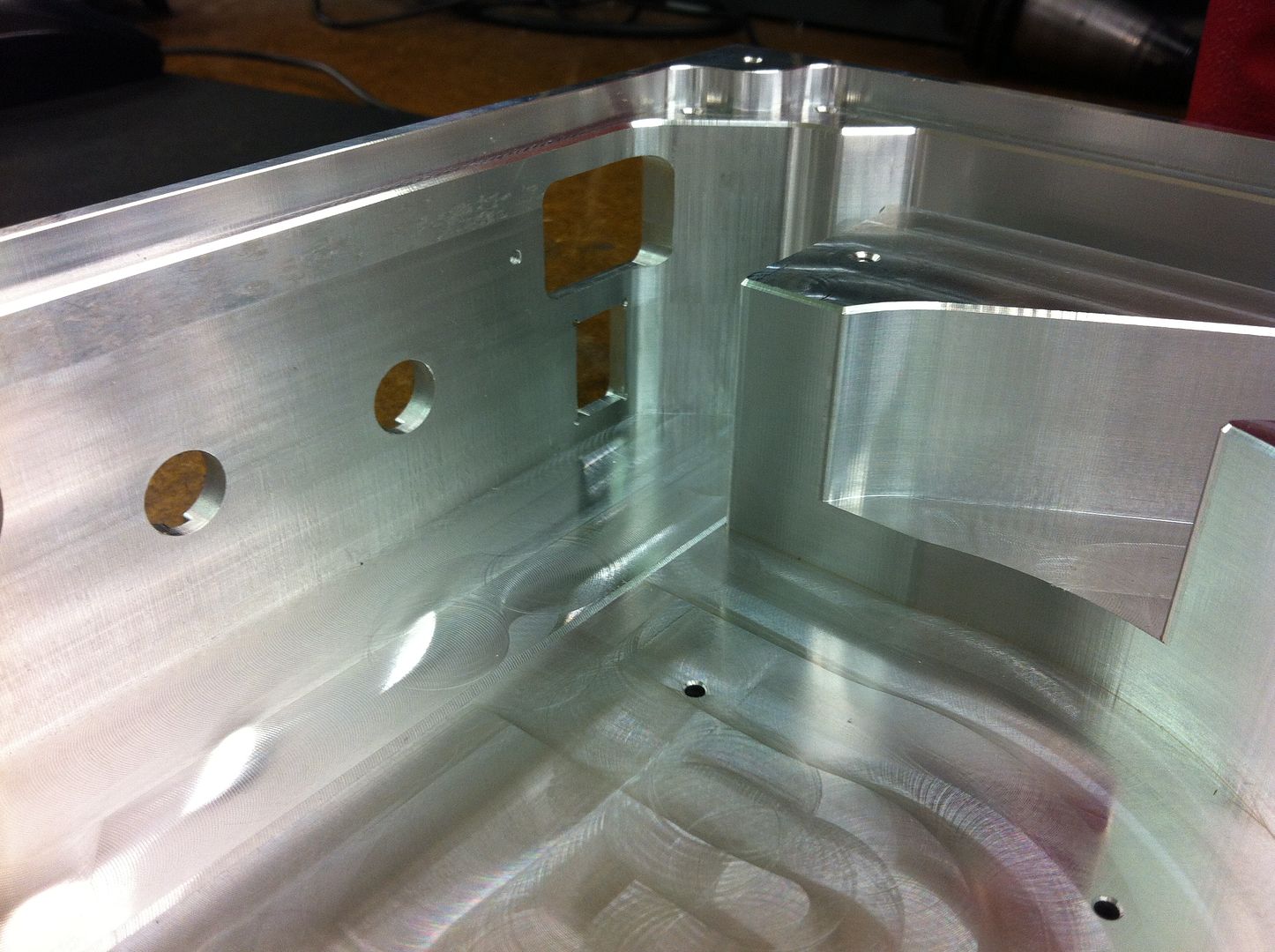

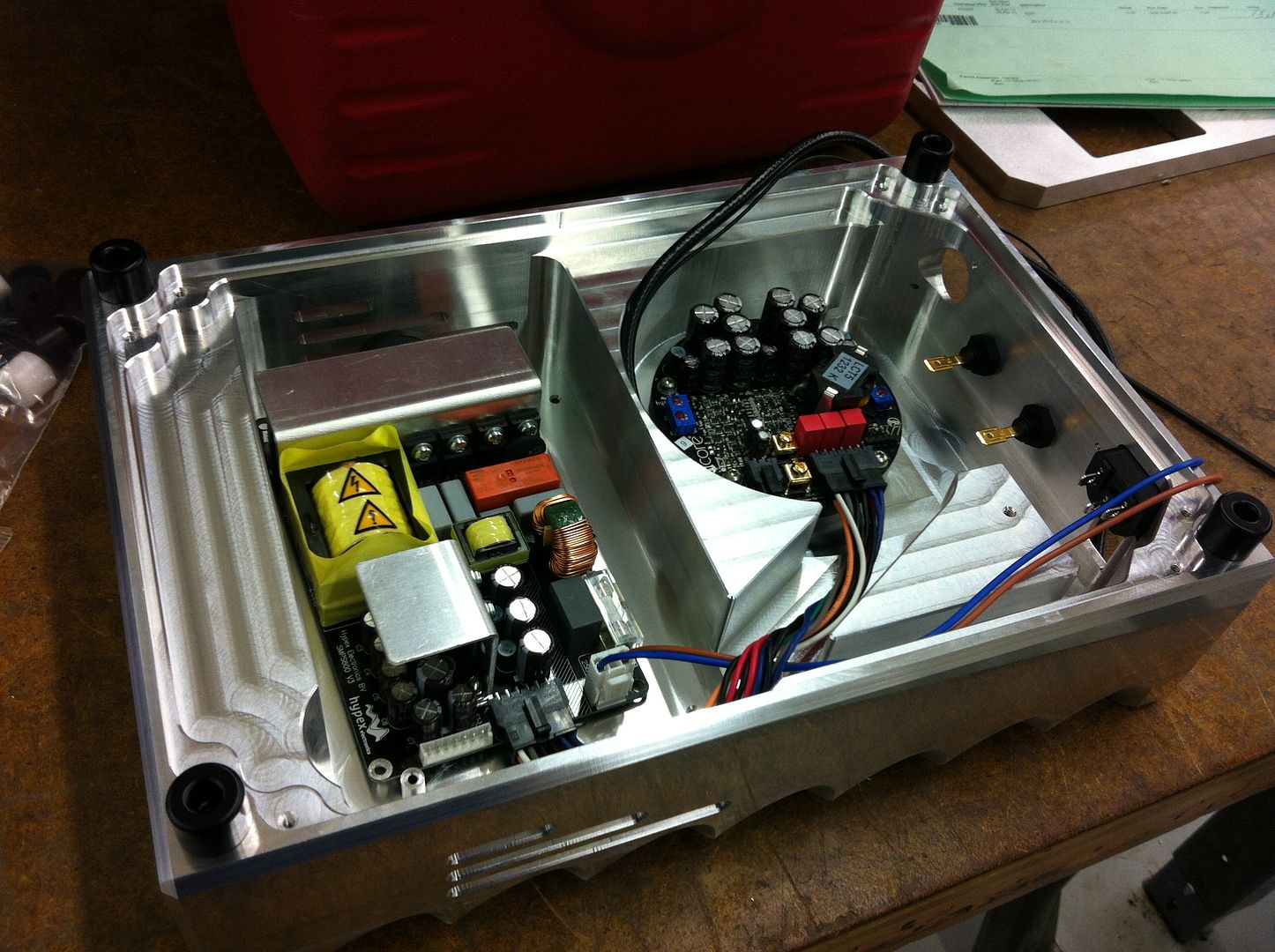

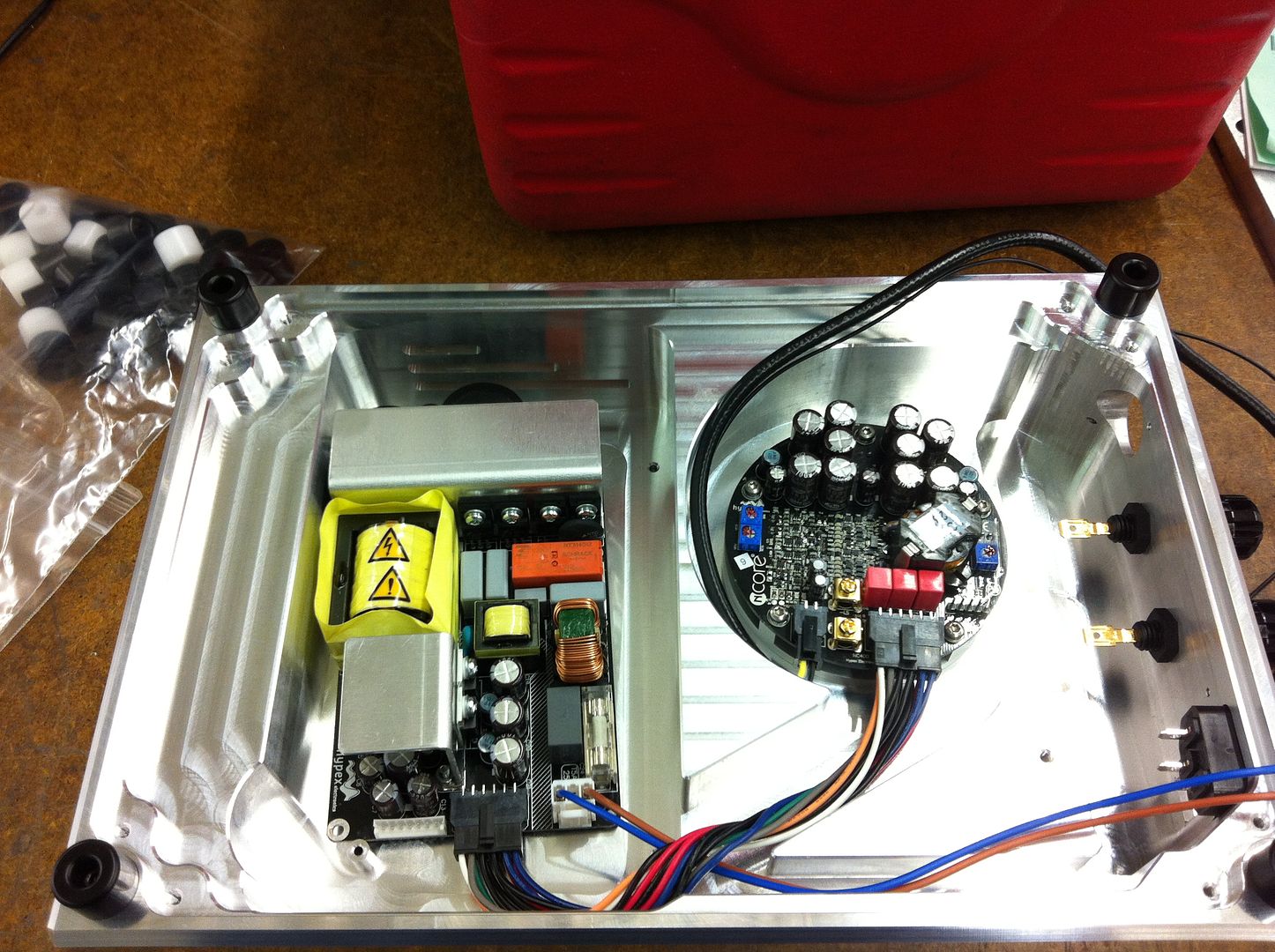

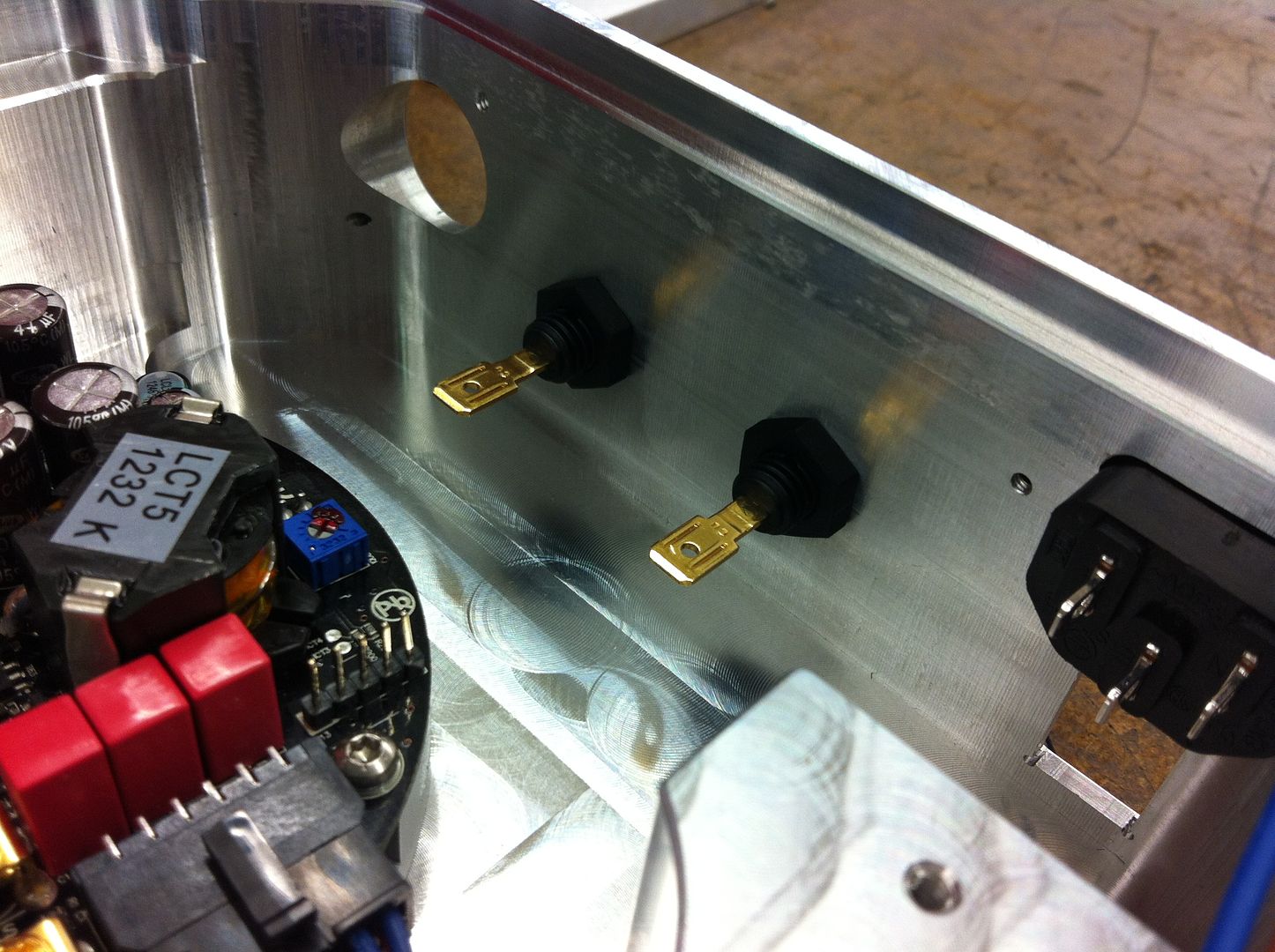

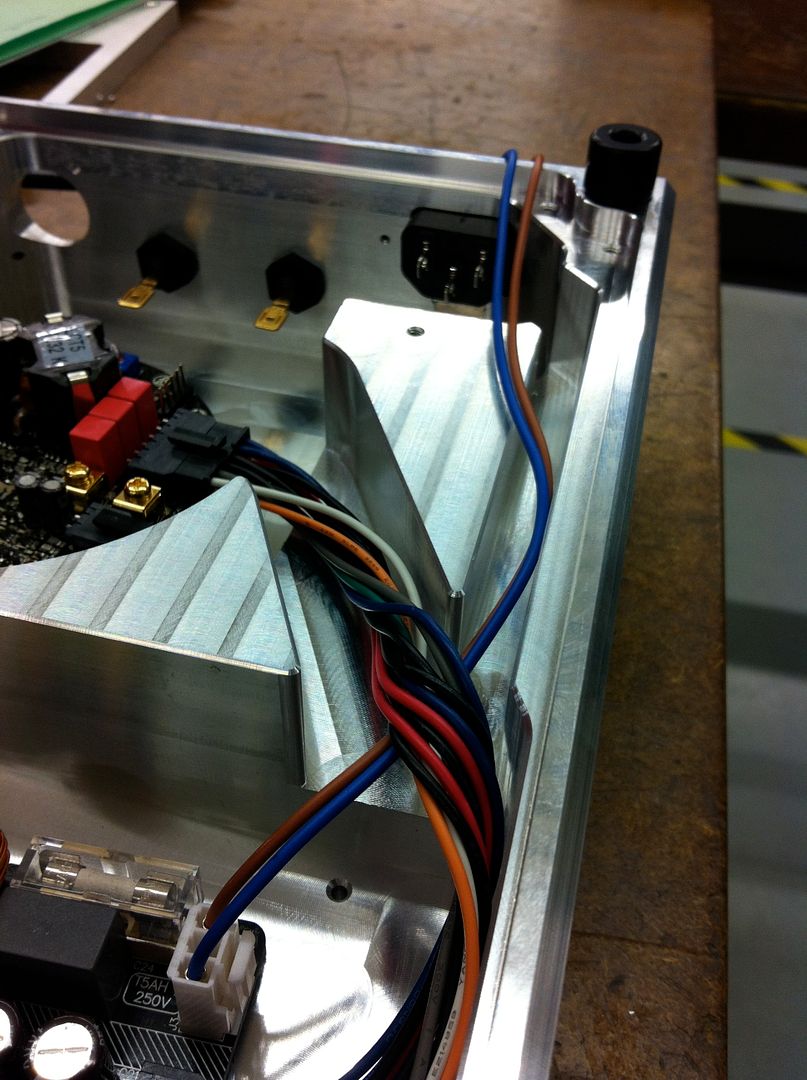

These cases weighed 29 1/2 pounds as raw stock, they ended up at 11 1/2 pounds after everything. A loss of 18 pounds from machining.

Matt