You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

JOB 225 2-channel Power Amplifier ... update ...

- Thread starter joeinid

- Start date

Hi Yami,Hello Wisnon,

Do you use your Lampizator with volume control directly on your JOB ?

I dont own a Job and the demo unit I has was returned a few days ago.

Also, my Lampi don't have VC, as I run them straight to my Integrated. My pals with Lampi and Jobs, also use separate preamps.

Jack

Well-known member

mep

I am well aware of the differences between SL and Odyssey as well as the difference between the prices and intended target. It is from being the SL rep for decades that Klaus was able to get Rolf to support the use of SL designs and even parts to build a new line built to a price. Same intent as Goldmund had with the JOB line. If I wanted an SL I would have Klaus get me one as others have, but I would not try to mod an Odyssey to be an SL either.

I am well aware of the differences between SL and Odyssey as well as the difference between the prices and intended target. It is from being the SL rep for decades that Klaus was able to get Rolf to support the use of SL designs and even parts to build a new line built to a price. Same intent as Goldmund had with the JOB line. If I wanted an SL I would have Klaus get me one as others have, but I would not try to mod an Odyssey to be an SL either.

mep

Well-known member

- Joined

- Dec 4, 2013

- Messages

- 5,359

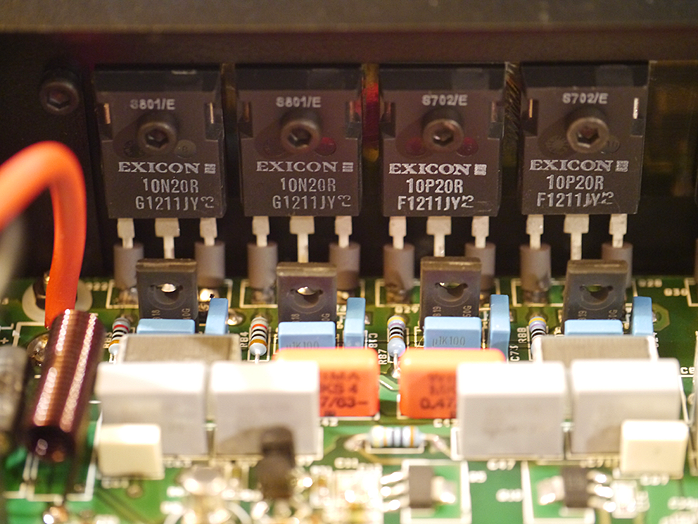

Jack-Sorry I misunderstood your point. I thought you were trying to say they were both very close in performance. With regards to the JOB vs. Goldmund. I think those are much closer in terms of design and parts. The CCA for the JOB looks just like the CCA in the Goldmund minus a few parts which I believe are capacitors and look like they could easily be added to the board if you knew what the values were. If I owned a JOB, this would be the path I would be traveling down first and not the IEC connector and input and output connectors. Making the CCAs identical will make a difference to the sound vice the imagined differences with fuses, IEC connectors, and input/output connectors. If I wasn't doing the soldering myself, I would try and find a technician in your area that has current J-STD solder certifications so they won't do any damage to your CCA and will do a first class soldering job and not the Tommy 10 Thumbs special.

Is your Job straight?

Mine certenley is not. It will wobble on 3 feet... and there is no way to make 4 of them contact the leveled surface.

Any views on topic?

Cheers,

seb

i will take it.

Jack-Sorry I misunderstood your point. I thought you were trying to say they were both very close in performance. With regards to the JOB vs. Goldmund. I think those are much closer in terms of design and parts. The CCA for the JOB looks just like the CCA in the Goldmund minus a few parts which I believe are capacitors and look like they could easily be added to the board if you knew what the values were. If I owned a JOB, this would be the path I would be traveling down first and not the IEC connector and input and output connectors. Making the CCAs identical will make a difference to the sound vice the imagined differences with fuses, IEC connectors, and input/output connectors. If I wasn't doing the soldering myself, I would try and find a technician in your area that has current J-STD solder certifications so they won't do any damage to your CCA and will do a first class soldering job and not the Tommy 10 Thumbs special.

'' the imagined differences with fuses, IEC connectors, and input/output connectors. ''

So when you order your custom made $20K amp you instruct them to build it with ALL cheap A$$ connectors and have them make sure the 50 cents fuse goes in also because there is no difference from the better HE connectors/fuse ?

Why not get your thought across without tearing down something you have no experience with?

mep

Well-known member

- Joined

- Dec 4, 2013

- Messages

- 5,359

'' the imagined differences with fuses, IEC connectors, and input/output connectors. ''

So when you order your custom made $20K amp you instruct them to build it with ALL cheap A$$ connectors and have them make sure the 50 cents fuse goes in also because there is no difference from the better HE connectors/fuse ?

Why not get your thought across without tearing down something you have no experience with?

Who is talking about a $20k amp? Where did that come from? If you reread what I wrote, my point is that if you really want to improve the sound of your JOB amp, I would be figuring out what it would take to make the CCA look just like it's big brother's CCA. Goldmund left some parts off of the CCA that goes in the JOB.

And another thing...I have built tube amps and preamps from scratch. When I build my own gear, I buy WBT input connectors and binding posts. Why? Because they are very well made, structurally strong, and I know I don't have to worry about them being a weakness in the design. Companies like McIntosh, Marantz, and Audio Research used barrier strips for many years for their amps in order to connect your speakers. After the birth of fancy speaker cables and huge spade lugs, barrier strips fell out of vogue. It's not because there was anything wrong with the way they "sounded," it's because they just didn't work correctly with designer cables. So yeah, I want to make a nice tight connection between my speaker cable and my binding post, but I don't believe the binding post is going to increase my sound quality. It will increase your bling quality though which makes some people feel better and when you feel better, it's easier to imagine that your system sounds better.

With regards to fuses, I haven't joined the fuse voodoo cult. Fuses are a necessary evil in circuit designs and they are there to protect the gear from self-destructing and possibly starting a fire that will burn your house down. I'm not going to take a chance on messing with the electrical integrity of an audio component by substituting an audiophile fuse that may or may not meet the actual ratings of the fuse it replaced. If you think sticking an audiophile fuse in your gear is a real game-changer in terms of SQ, by all means use them and be happy. Just keep your fingers crossed that the fuse will work like it's supposed to in case something happens and it needs to blow.

Glareskin

Member

100 pages!

this little amp is really something!

this little amp is really something!

100 pages!

this little amp is really something!

From the Netherlands yes? You know Peter from Phasure NOS1? Killer stuff he has and the Job amp works great with his Dac/Computer.

Glareskin

Member

Right.From the Netherlands yes?

I don't know him. Is that the Metrum NOS DAC? I know that is a popular device in The Netherlands.You know Peter from Phasure NOS1? Killer stuff he has and the Job amp works great with his Dac/Computer.

maty

New member

I stripped 3 screws on the top cover and still can not get the cover off. Why do they insist on having small screws heads and tightening them so tight one can not remove them??

maty

New member

Maybe you need a torx screwdriver.

Wikipedia Torx

I had to buy one to open my ODAC (DAC USB designed by NwAvGuy).

Wikipedia Torx

Torx (pronounced "torks"), developed in 1967[1] by Camcar Textron,[2] is the trademark for a type of screw head characterized by a 6-point star-shaped pattern. A popular generic name for the drive is star, as in star screwdriver or star bits. The official generic name, standardized by the International Organization for Standardization as ISO 10664, is hexalobular internal.[3] This is sometimes abbreviated in databases and catalogs as 6lobe (starting with numeral "6", not a capital "G"). Torx Plus is an improved head profile...

I had to buy one to open my ODAC (DAC USB designed by NwAvGuy).

Hello, I just purchased the Job 225 today and it should arrive next tuesday. This is my set-up.

Shuntaya Venom 3 power cords and Mapleshade Double Helix Plus speaker cables and Mapleshade Excalibur Plus analog IC.

Going from Cambridge Audio 752BD (was close to going with Oppo 105 but decided to go with CA)-> Job 225 -> Evolution Acoustics MicroOnes.

Will leave impression when I get the Job 225 next week!

Shuntaya Venom 3 power cords and Mapleshade Double Helix Plus speaker cables and Mapleshade Excalibur Plus analog IC.

Going from Cambridge Audio 752BD (was close to going with Oppo 105 but decided to go with CA)-> Job 225 -> Evolution Acoustics MicroOnes.

Will leave impression when I get the Job 225 next week!