brad225

Well-known member

- Thread Author

- #1

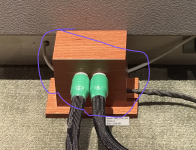

This will have pics from 2 different builds but the process is the same.

I had 2 wires that were either positive or common with tape of some color to keep track that they were always opposite each other when twisted.

The wires above were twisted and taped. The wire extending out of the wrapping were untwisted from what is inside the taped area.

More to come. Company just showed up and I need to play host.

I had 2 wires that were either positive or common with tape of some color to keep track that they were always opposite each other when twisted.

The wires above were twisted and taped. The wire extending out of the wrapping were untwisted from what is inside the taped area.

More to come. Company just showed up and I need to play host.