The veneer I use in Bulgaria is known as "Birds of Maple", in the world is also known as "Bird's eye" . We reach the moment of very specific activity - veneering with natural veneer. When veneering panels, details is in one plane, there are no problems. There is only a requirement - the person who collects the individual pieces has good skills, the rest is completed by the pneumatic press.

When we talk about a complex shape, our immediate association is for "Vacuum press", but there is a limit to the thickness / height / of the workpiece. If we are talking about veneering of a flat surface with motifs on the surface - it does work, but if it is another massive form- don’t.

Due to the complexity of the process, i will pay close attention to it. My technique is complex, risky on a large scale and I definitely do not recommend it to enthusiasts with little experience! A natural veneer can bend tangentially or radially, usually masters prefer to work in just one direction - for less headaches. In my method of processing, I use both bending directions simultaneously, but add a third diagonal bending.

The other main problem is the adhesive with which it sticks the veneer, it is polychloroprene, this glue does not allow you to move the veneer, once touched to the base there is no other chance-stays there. If you try to move it, you will break the veneer at the moment, and when we talk about "Birds of Maple" with a price over 60 EUR, the feeling it's not pleasant!

I will explain my technique for cutting veneer before gluing it.

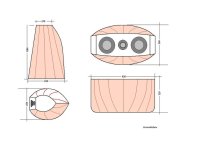

On the finished cabinet of the loudspeaker, from " India paper" / she is the closest with the veneer / I make the templates that should lie perfectly on the base. The problem is in the wrong shape, the veneer after gluing in one part, changes his shape, although everything has previously been matched perfectly. It requires a lot of attention, patience, and proper judgment, which part should squeeze, otherwise balloon spaces are created, which are very difficult to correct without being visible later. Sometimes, depending on the type of veneer, moistening helps, but this action also requires judgment with experience.