ohbythebay

New member

- Thread Author

- #21

Yes, it is called spindle to pivot distance. On any given tone arm, there is an optimal distance and placement.

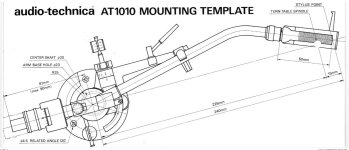

One does this with a template or a measurement by measuring from the spindle in a direct line to the pivot. See example below but note...not every arm is the same (though many are). Knowing that number can help you build your or table or add an arm to a table that allows it.

One does this with a template or a measurement by measuring from the spindle in a direct line to the pivot. See example below but note...not every arm is the same (though many are). Knowing that number can help you build your or table or add an arm to a table that allows it.